In metal roofing and wall systems, material choice directly impacts service life, maintenance cost, and project risk. While several coated steel substrates are available on the market, galvanized steel continues to be used in specific applications where its properties match the operating environment.

This article focuses on where galvanized steel performs well, where it does not, and how to judge whether it is suitable for a given project—without revisiting basic definitions.

Typical Applications of Galvanized Steel Roofing

Although newer alloy-coated substrates are widely adopted today, galvanized steel is still used in the following scenarios:

Galvanized roofing panels are commonly produced in 22–29 gauge, and can be supplied with painted systems such as SMP or PVDF, depending on durability requirements.

From a structural perspective, galvanized steel panels follow the same design logic as other coated steels—load capacity is determined by steel thickness and yield strength, not by the coating itself.

Key Advantages in Real-World Use

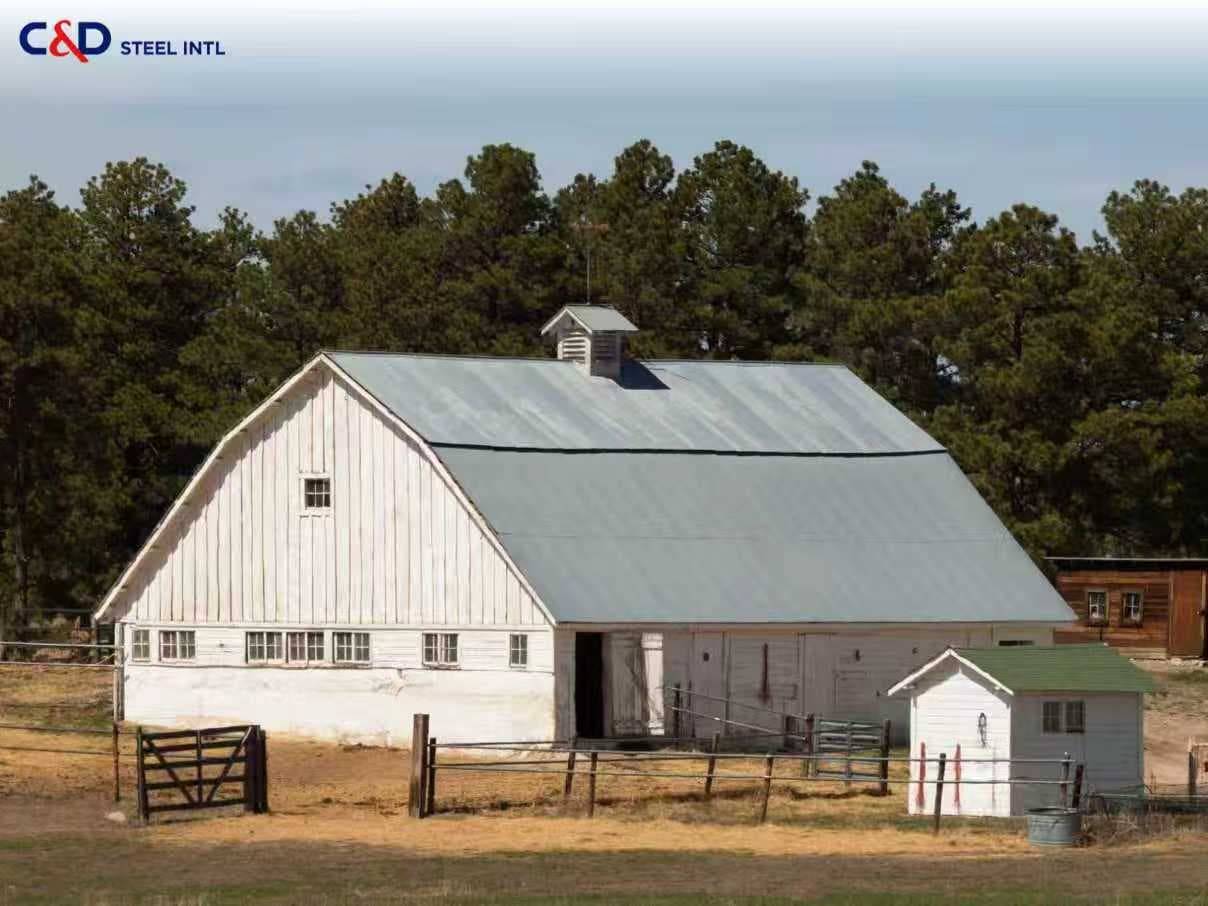

1. Better Performance in Animal Confinement Facilities

In livestock buildings, ammonia gas generated from manure can aggressively attack aluminum-containing coatings. In these environments, galvanized steel often performs more reliably, provided that ventilation and moisture control are properly managed.

3. Distinct Visual Appearance

Certain projects intentionally specify galvanized-based products for their industrial or vintage metallic aesthetic, especially in architectural or renovation projects where appearance matters as much as function.

4. Flexible Cost Positioning

Depending on market conditions, galvanized steel may be competitively priced for short- to mid-term projects where extended service life warranties are not required.

Limitations and Risk Factors

1. Limited Warranty Coverage

Most galvanized roofing systems do not include long-term substrate warranties, especially for corrosion resistance. This can increase lifecycle risk for projects with long design lives.

2. Red Rust Propagation

Once the zinc coating is locally damaged—particularly at cut edges—the exposed steel can develop red rust, which continues to spread rather than stabilizing over time.

3. Shorter Expected Service Life

In typical non-aggressive environments, galvanized roofing systems often deliver 15–20 years of service life, significantly shorter than alloy-coated alternatives.

4. Not Suitable for Coastal or Marine Environments

Salt exposure accelerates zinc consumption. As a result, galvanized steel is not recommended for coastal, offshore, or high-salinity regions, where corrosion rates increase sharply.

5. Oil Canning (Cosmetic Issue)

Like all light-gauge metal panels, galvanized steel may show oil canning—visible waviness in flat areas. While this does not affect structural performance, it can be a concern for architectural projects.

When Does Galvanized Steel Make Sense?

Galvanized steel may be a reasonable choice when:

For projects emphasizing long-term durability, corrosion warranties, and minimal maintenance, other coated steel or aluminum substrates are typically more appropriate.

Conclusion

Galvanized steel remains a functional, application-specific solution rather than a universal one. Its performance and value depend heavily on environmental exposure, design expectations, and lifecycle planning. Selecting the right roofing substrate is not about choosing the most familiar material—it is about aligning material behavior with real operating conditions and project priorities.

For projects that require a clearer understanding of galvanized steel specifications, application limits, or sourcing feasibility, our team supports global clients across construction, energy, and industrial sectors. We work closely with project owners, contractors, and manufacturers to translate technical requirements into practical material solutions.

📧 E-mail: cfloffice@chinacnd.com

📱 WhatsApp: +86 173 1931 2767

☎ Tel: +86 0592 259 2583

📍 Address: 21F C&D International Building, No.1699 Huandao East Road, Xiamen, 361008, China

Copyright @ 2026 CHEONGFULI (XIAMEN) CO.,LTD. All Rights Reserved. Network Supported Sitemap / Blog /

Xml / Privacy Policy

Network Supported Sitemap / Blog /

Xml / Privacy Policy